With the involvement of human workforce in every process in the manufacturing industries, there are increased chances of errors, frequent failures, and problems in maintaining the productivity and quality of products. Owing to these circumstances, implementation of SCARA robots becomes very essential for manufacturing firms. SCARA robots are horizontally configured robots with fewer backend-programming requirements. These robots can accelerate cycle times, increase throughput, and eliminate bottlenecks.

SCARA robots in industries has numerous advantages such as decreased manufacturing cost, shorter cycle time, improved quality and reliability, better floor space utilization, reduced waste, increased safety and overall expertise in multiple applications. The analysts at Technavio forecast global SCARA robots market to reach above 54 thousand units over the period from 2017 to 2021, growing at a CAGR of 5 plus percent.

The electronics, electricals and automotive industry are the major growth drivers for global SCARA robots market amounting to nearly 50 percent of the market share together.

SCARA Robots: Faster, Reliable and Productive

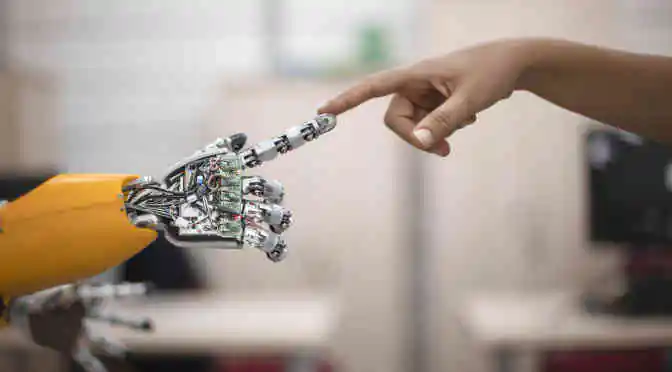

Manufacturing industries including automotive, pharma, electrical and electronics, metals, rubber, food and beverages are compulsorily adopting automation in their plants to prevent human errors, wastage of materials, repetitive jobs, and exhaustion of human workforce with continues work on the floor. Thus, resulting in increased demand for robotics.

The critical applications in the manufacturing firms entails the replacement of human workforce by robots to ensure the safety of human workers and to improve efficiency of work. Hence, the rising adoption of robotics in manufacturing industries is a major driving factor for the global SCARA robots market.

SCARA robots are highly used in mechanical operations such as packaging or stacking items on pallets or surfaces. The rigid parallel joints in the structure of SCARA robots that are positioned vertically, including the payload capacities and arm movements makes these robots flexible while stacking up material accurately on the required platform. These outstanding features in SCARA robots escalates their market demand.

There are many vendors in the market manufacturing SCARA robots at a low cost. Manufacturing firms avail tremendous advantage by purchasing these robots owing to low cost and high-speed capabilities. KUKA and Toshiba are the leading firms manufacturing cost-effective SCARA robots.

The Prominent End-user Industries

- Electrical and electronics industry

- Automotive industry

- Rubber and plastic industry

- Food and beverages industry

- Heavy machinery industry

- Metal industry

Technavio Market Solutions

A comprehensive study is done by Technavio to deliver a strong understanding of the market to the firms in Global SCARA Robots Market. The report comprises of an in-depth primary and secondary research to provide market insights to the firms in the same or related industry. Our report also covers a detailed analysis of industry including key drivers, emerging trends, as well as the competitive landscape.