To celebrate the fact that like several other businesses, the chemicals industry too has finally opened to digitalization will be a flimsy affair. This is purely because, for an industry which employs around 20 million people globally, low digital maturity is rather a matter of concern and calls for deep introspection.

Chemicals industry and the dismal state of digital maturity

The dismal state of digitalization in the chemicals sector can be explained by the fact that even today, many chemical companies have not understood the fact that their IT department and digital transformation are two different things. IT department can at the most be a facilitator of the digital transformation and not the enabler. This explains why more than 50% of chemical companies do not have any digital transformation strategy in place.

According to our lead analyst in the chemicals and materials sector, Ajay Adhikari, at the global level, it is the European chemicals companies which are displaying a lot more digital maturity as compared to players from the Americas and the APAC region. He is also of the view that the chemical enterprises dealing with specialties have a greater digital footprint as compared to the other categories in the chemicals industry.

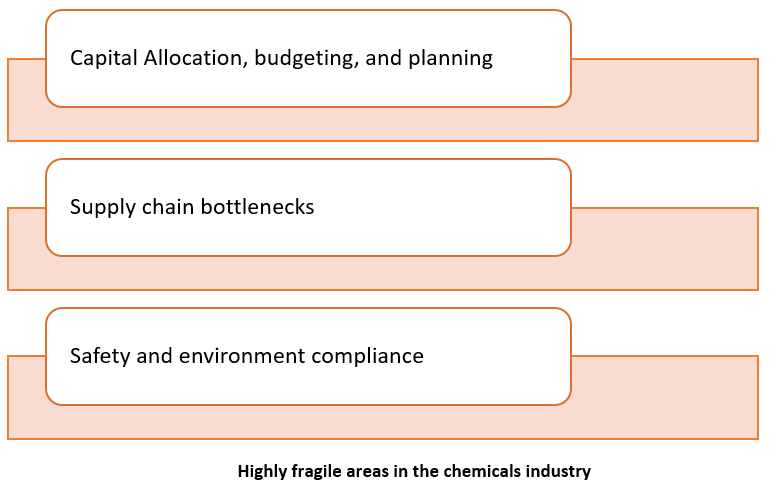

Highly fragile areas in the chemicals industry

A highly reactive industry, players in the chemicals market regularly face a crisis in their value chain system. Chokepoints in the production process, commercial operations, talent acquisition, and management, have turned into everyday challenges which they try to overcome painfully.

Issues like poor collaboration between suppliers and clients, lack of cross-site streamlining of resources, poor portfolio management, and compliance with safety regulations, call for an efficient handling of the entire chemicals value chain process. Intelligent use of digital enablers is sure to add more strength to the industry, bring in more transparency, and encourage the diligent use of resources.

Is the ground ready for digitalization of the chemicals industry?

Industry experts see digitalization as a catalyst which will promote innovation and thereby transform the functioning of the chemicals industry. At present, the industry is struggling to streamline its M&A activities and fasten its seatbelts to meet the emerging challenges. Industry leaders have accepted the fact that when synergized with the right strategies and backed with the required digital capabilities, digitalization is sure to provide more value to the entire supply chain process.

Here is what happens when digital solutions enter the chemicals industry:

1) Profitable operations

By building digitally enabled intelligent chemicals plants, manufacturers upscale their operations and gain end-to-end financial visibility. The result of such an integration is reduced risk, better waste management, optimization of the production network, and most of all better workforce safety.

2) Better supply chain management

Managing the supply chain has been a major pain point for almost all the major names in the chemicals industry. Digitalization of stock and fleet management plays a critical role in building an agile transportation system. An indirect result of adopting digital solution in supply chain management is the resultant optimization of the spend services along with better compliance with the tracking regulations laid down by authorities. The digital supply chain also enables suppliers to reach out to customers in new markets and geographical areas.

3) Improved marketing and sales results

Lack of clear insight on the competitive landscape has been a major factor behind failed marketing and sales strategies. Digital transformation leads to better ability to respond to the latest trends and cyclicality of the market. A comprehensive understanding of the market obviously results in better customer awareness which can be easily translated to improved marketing and sales results.

4) Digital marketplace presence

As an extension of improved sales and marketing results, digitization of business also results in enhanced marketplace presence. Insights from social listening programs facilitate better tracking of customer sentiments. Just having a clearer knowledge about what your end-user is looking for, places you in a better market position and enhances the overall visibility of the brand. The overall result is better identification of new opportunities and risk mitigation.

5) Digitized workplace

Lastly, digital transformation results in the evolution of highly digitalized and sophisticated workplace culture. Digital technologies play a critical role in improving the overall efficiency of the organization by facilitating better workforce collaboration, providing visibility, and enabling better financial decisions. Cloud-based talent management solutions which are an integral part of digitalization, also help entrepreneurs in performance management and risk compliance.

Now, coming to the question – is the chemical industry all set for this transformation? As already mentioned, the chemical companies dealing with specialty chemicals have already embraced digitalization, and are rather moving towards the mature stage. So, even though the industry is all set to embrace digitalization, there are gaps in the pace at which various verticals will adopt it.

Therefore, even though it is not clear whether the ground is fully ready to unleash the potential of the digital medium – one thing is quite loud and clear, digitalization is sure to bring in a lot of disruptions in the chemicals industry. And, with disruption comes a bundle of opportunities for innovation, expansion, and growth. What is needed is that stakeholders adopt operating models which synchronize their business plans and digital solutions, streamline collaboration with business partners in this new ecosystem, and position value chains which rein in efficiency and transparency.

To get all the latest updates about the chemicals and materials sectors, read our latest reports